Structural Steel Beam

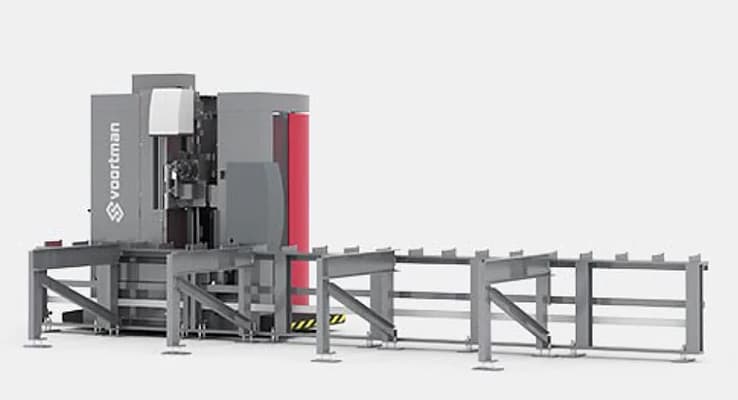

The CNC Drill Line is easy to use and Avenger workers were the ones who laid the floors. There is no need to know anything about computers, and all training is given during the installation.

Voortman offers regular training classes on all Voortman or Ocean equipment at their Bradley Illinois location. These courses can be used to refresh existing operators or for those who are just starting out. This facility will ensure that your employees return to work motivated and well-trained. Call for pricing and details.